Over the past 20 years, Bluey has completed waterproofing on hundreds of cross-passages, all of which have met the ‘no damp patches’ specification for rail infrastructure.

All cross-passage entrances have curvature in three planes, making membrane installation, steel fixing and concreting far more complex than other tunnelling applications.

The geometry adds particular challenges for the Waterproofing Technicians, as the surfaces differ over short lengths resulting in a high frequency of welds per square metre of membrane installed.

The detailed engineering of critical elements such as the membrane termination to the TBM segments becomes a critical factor in tunnel waterproofing success. This is why so much time and effort has been applied to its research and development.

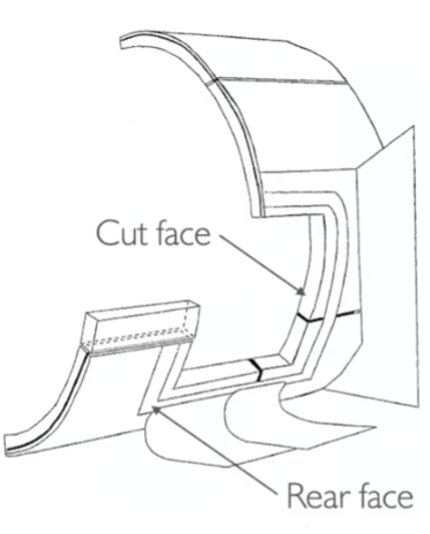

When joining the membrane to the TBM segments, Engineers may choose to terminate the membrane to the rear side of the segment, or to the cut face of the segment.

The reasons and key considerations for both are outlined below:

Rear Face Fixed:

- Requires greater excavation space behind to create 200mm lip on segments for placement of gasket

- TBM gaskets can be placed at any location on the segment cross-section

- Requires connection from membrane termination seal to the TBM lining segment gaskets

- Provides smoother surface for pressure termination seal to compress against.

Cut Face Fixed:

- If location permits, direct connection of the membrane gasket can be made to the TBM lining gasket

- No requirement to excavate extensively behind the segments

- TBM gaskets are usually located toward the rear face of the segment so the membrane termination must have a sealing connection to this.

- Requires neater cutting of lining segments and more surface preparation.

Whether cut face or rear face, the critical factor is that there must be continuity with the TBM gaskets, as when tunnelling and waterproofing below the water table, there are no second chances.

Most recently, we successfully sealed all four cross passages below Sydney Harbour and are excited to complete many more in the coming years. To learn more about cross passage waterproofing, watch the Waterproofing TBM Cross Passages webinar or visit the product page below.

Other articles:

The Checklist for Tunnel Waterproofing Success – Part 1

The Checklist for Tunnel Waterproofing Success – Part 2